Over the past few years, Print on Demand has no longer been an “easy-win” playground. As advertising costs continue to rise, markets become saturated more quickly, and trend life cycles grow increasingly shorter, POD sellers are forced to confront a core question: how can products be tested faster and at lower cost while still maintaining the ability to scale when positive signals appear?

The launch of the BASIC DTF production line is seen as a direct answer to this challenge. Rather than positioning itself as a premium solution or focusing on visual branding, BASIC DTF concentrates on what sellers care about most in the early and mid stages of their business journey: cost efficiency, flexibility, and scalability.

What Is BASIC DTF?

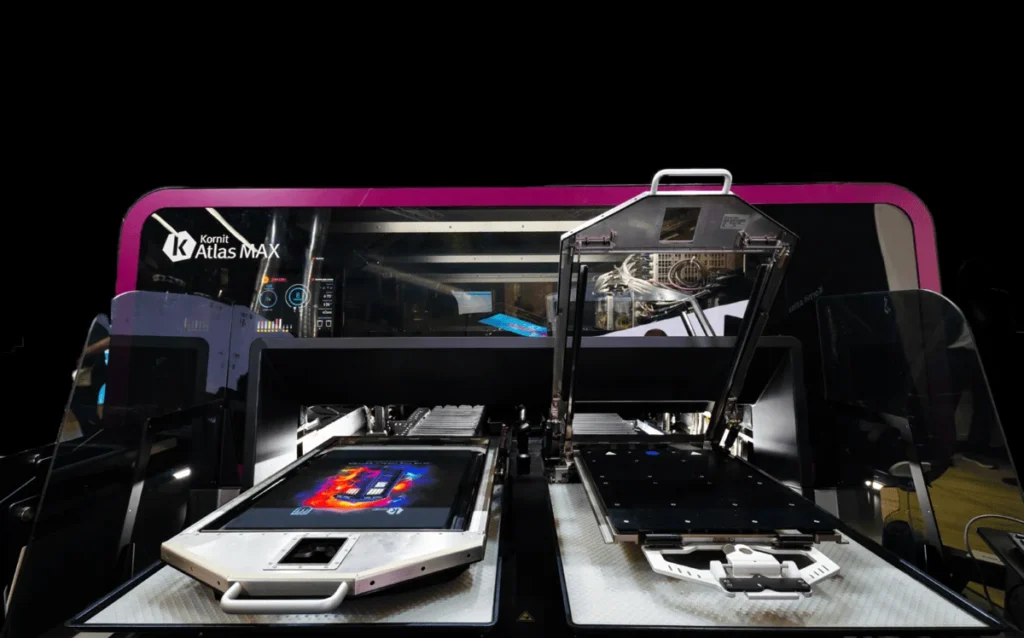

BASIC DTF is a production line that applies Direct to Film (DTF) printing technology, a method in which designs are printed onto a specialized film and then heat-pressed onto garments. DTF technology is already well known within the POD community for its flexibility and its ability to accommodate a wide range of designs and fabric types.

What sets BASIC DTF apart is not the printing technology itself, but the way the production process is structured and optimized. This approach enables a lower base cost, making BASIC DTF ideal for market testing and for scaling large order volumes within a short period of time.

Why Did BASIC DTF Emerge at the Right Time?

In recent years, the operational reality faced by POD sellers has revealed an increasingly clear paradox: sellers are required to test more frequently in order to identify winning products, yet the cost of each test continues to rise. The POD market no longer leaves room for intuitive or high-risk experimentation. Shorter trend life cycles, rapidly changing consumer behavior, and intensifying competition have made testing designs, niches, and messaging a mandatory activity for sellers who want to survive and grow.

However, high production base costs have become a major barrier during the testing phase. When printing costs account for a large portion of the selling price, sellers are forced to think carefully before launching new products. As a result, design testing is no longer conducted as broadly or consistently as before, and is often delayed due to risk concerns. At the same time, advertising budgets are quickly depleted when the remaining margin after production costs is insufficient to sustain extended testing campaigns. The consequence is that many sellers recognize market signals but hesitate to scale or scale too slowly ultimately losing valuable timing advantages.

In this context, the core challenge is not about finding more new trends, but about optimizing input costs so that testing becomes financially safer. Sellers need a production line that allows them to experiment with more ideas, accept a higher failure rate, and still maintain overall risk control. This is precisely the gap that BASIC DTF was designed to fill.

BASIC DTF was developed as a production line with low input costs, a streamlined workflow, and sufficient stability to support commercial sales. Rather than positioning itself in the premium segment, this line directly addresses sellers’ core challenge: how to test faster, at lower cost, and scale more easily when a product shows positive signals. When base costs are reduced to a reasonable level, testing no longer feels like financial pressure it becomes a natural part of a sustainable growth strategy.

For this reason, the emergence of BASIC DTF is not accidental. It reflects the real needs of today’s POD market: a practical, flexible production solution aligned with test-and-scale strategies in a highly competitive environment.

Core Advantages of BASIC DTF

In today’s POD landscape, choosing a production line is no longer just about printing technology it directly determines a seller’s ability to test products, optimize costs, and scale operations. BASIC DTF is built around these core advantages, designed to meet the real operational needs of POD sellers.

First and foremost, low base cost is the most prominent advantage of BASIC DTF. With base costs starting from $4.8, sellers can test a wider range of designs within the same budget without excessive cost pressure. This allows for a higher acceptable failure rate when searching for winning products, while also optimizing advertising strategies in the early stages. When testing costs are kept under control, decisions around design, niche selection, and scaling are no longer driven by intuition, but guided by real performance data.

In addition, BASIC DTF does not require a minimum order quantity (MOQ), providing significant flexibility for sellers at all scales. Whether a seller is fulfilling just a few orders per day or entering a rapid growth phase, production costs remain optimized. This flexibility is especially critical in the POD environment, where demand can shift quickly with trends and seasonal changes.

In terms of quality, although positioned as a “Basic” line, BASIC DTF fully meets the standards required for commercial sales. Print clarity, strong adhesion, and compatibility with typography, graphic designs, and simple layouts allow sellers to confidently fulfill large volumes in short timeframes.

A common concern when sellers consider low-base cost production lines is whether material quality is compromised. With BASIC DTF, the answer lies in smart cost optimization, not in lowering input standards.

The films, inks, and garment blanks used in BASIC DTF follow the same quality standards applied across FlashShip’s other production lines. The difference does not come from using cheaper materials, but from a more streamlined production process that eliminates unnecessary steps for fast testing and scaling objectives.

As a result, BASIC DTF prints maintain the necessary sharpness, adhesion, and stability for commercial sales particularly well-suited for text-based designs, simple graphics, or ad-optimized layouts. Sellers can confidently run large-scale tests without worrying about print quality falling below customer expectations.

In other words, BASIC DTF is a cost-optimized line through process efficiency, not a line that sacrifices quality for lower pricing. This is what enables sellers to manage financial risk while maintaining a quality level that is safe and reliable for selling, testing, and scaling in a highly competitive POD market.

Finally, thanks to its optimized workflow, BASIC DTF allows sellers to scale more easily and reduce operational pressure. When campaigns show positive signals, increasing order volume, launching promotions, bundles, or upsells becomes faster and more controllable. In a highly competitive market, this speed of response is what creates a true competitive advantage for POD sellers.

Which Sellers Is BASIC DTF Best Suited For?

Within the Print on Demand ecosystem, not every seller needs to start with premium production lines. In reality, most growth journeys begin in the testing phase, where cost control and risk management play a decisive role. BASIC DTF was developed specifically to serve this need.

First, this production line is well suited for new POD sellers who are still getting familiar with the market. Without sufficient sales data, high testing costs can create unnecessary pressure and limit experimentation. BASIC DTF allows new sellers to enter the market more safely, test more ideas, and learn faster.

In addition, sellers who frequently test niches, trends, and designs will see clear benefits. With constant experimentation as part of their strategy, lower production costs enable sellers to expand their testing scope while maintaining healthy cash flow an increasingly important advantage as trend life cycles continue to shorten.

BASIC DTF is also ideal for sellers looking to expand their product catalog without letting production costs scale proportionally with the number of listings. Furthermore, sellers running short-term campaigns that prioritize speed and efficiency can leverage this line to scale quickly once a product shows positive signals.

BASIC DTF is not designed to “polish brand image,” but rather to help sellers identify winning products faster and optimize overall business performance.

The Role of BASIC DTF in a Long-Term POD Strategy

In modern Print on Demand strategies, sellers no longer rely on a single production line for their entire business. Instead, the prevailing approach is to segment production lines based on specific use cases, allowing sellers to optimize both short-term costs and long-term value. Within this framework, BASIC DTF plays a foundational role in the testing and growth stages.

With its low input costs and flexible operations, BASIC DTF is positioned as a cost-efficient line for testing and scaling. Sellers can continuously experiment with designs, niches, and advertising campaigns without placing excessive pressure on cash flow. Once a product demonstrates consistent sales performance, sellers can proactively transition to higher-quality production lines to enhance customer experience, increase average order value, and build a sustainable brand.

This approach enables POD sellers to manage risk more effectively, make data-driven decisions, and maintain stable long-term growth rather than being locked into a single, fixed production model.

In this broader strategy, BASIC DTF serves as the testing and growth foundation, helping sellers minimize risk and optimize cash flow before expanding into higher-tier segments with FlashShip. BASIC DTF is not a production line designed to “showcase technology,” but a practical solution that accurately reflects how POD sellers operate in today’s highly competitive environment. With its low base cost, high flexibility, and clear positioning for testing and scaling, BASIC DTF offers sellers a strategic option: better cost control, faster decision-making, and more proactive scalability. In a market where speed and efficiency determine success, BASIC DTF is not just a new production line it is a move aligned with the realities of modern POD business operations.