In the Print on Demand industry, printing technology not only determines product quality but also directly impacts conversion rates, customer satisfaction, and a seller’s ability to scale. The two most widely used technologies today are UV Printing and DTG (Direct to Garment), each with its own operating principles, suitable materials, and completely different output characteristics. Understanding the differences between UV and DTG allows sellers to choose the right products, optimize their designs, reduce refund risks, and build a more effective sales strategy. This article provides a comprehensive, detailed, and practical overview to help POD sellers make the right decisions for each campaign.

Why Do POD Sellers Need to Understand the Differences Between UV and DTG?

Many new sellers often make the mistake of assuming that “printing is all the same.” However, choosing the wrong printing technology for a design or material not only reduces the customer experience but can also lead to significant revenue loss. Below are four key reasons why you must clearly distinguish between these two technologies.

Design Accuracy When Printed on the Final Product

Each printing technology has its own strengths in how it processes and reproduces visual elements. If you do not understand these differences, the actual product will never achieve the visual quality you expect.

- For DTG printing: This is the optimal choice for full-color designs, portraits, and artwork with soft gradients. DTG allows the ink to penetrate the cotton fibers, resulting in a smooth finish and natural color transitions.

- For UV printing: This technology uses ultraviolet light to cure the ink instantly on the surface. As a result, UV excels at rendering fine lines, thin strokes, and small details that require high sharpness, especially on hard materials such as acrylic or wood.

Optimizing Customer Experience and Reviews

One of the most common reasons customers request a refund is: “The colors look darker/lighter in real life than on the website image.” The root cause lies in the color gamut and the way each printing technology renders colors differently.

- DTG tends to settle into the fabric, creating a natural or slightly vintage look, but sometimes appearing less vibrant than what is shown on screen.

- UV, on the other hand, creates a layer of ink that sits on the surface, producing extremely bright, glossy colors with strong contrast.

If you use a mockup designed to reflect DTG output but fulfill the order using UV printing (or vice versa), customers will feel visually misled the moment they open the package.

Optimizing Advertising Costs and Increasing Conversion Rates

Choosing the wrong material for a printing technology is a basic yet costly technical mistake.

- DTG requires apparel products with a high cotton content because cotton allows water-based ink to bond well and maintain color durability after multiple washes.

- UV printing, on the other hand, needs a hard, flat surface (such as plastic, metal, wood, or acrylic) so the ink can adhere properly after being cured under UV light.

Attempting to use UV printing on soft T-shirts, or applying DTG on non-absorbent surfaces, will cause the print to peel, crack, or fade quickly after only a short period of use.

Critical Risks When Scaling Campaigns

A lack of understanding about printing technologies becomes painfully obvious once you start scaling campaigns.

- Imagine running a T-shirt campaign using DTG-style mockups (soft, blended, fabric-integrated prints), but your fulfillment partner produces the orders using large-area decal or UV printing, which creates a stiff, heavy print. Customers will complain immediately.

- Conversely, if you are scaling ornament campaigns with designs built around DTG-style gradients or complex color transitions but the products are printed using UV, the final output will lack depth and the sharp detail required for a premium finish.

Overview of UV Printing Technology

In the modern Print on Demand (POD) industry, while DTG printing dominates the apparel segment, UV Printing has become the leading technology in the gift and decor categories. So how does this technology work, and why is it so important for sellers?

What Is UV Printing and How Is It Used in POD?

UV Printing (Ultraviolet Printing) is a technology that sprays ink directly onto the surface of a hard material. Its key distinction lies in the drying mechanism: immediately after the ink is applied, ultraviolet (UV) light cures the ink on the spot. This process allows the ink to adhere tightly to the material, prevents smudging, and produces exceptionally sharp print quality.

If you are selling hard goods, UV printing is the mandatory standard. It is the most widely used technology for producing best-selling POD products such as:

- Acrylic/Wooden Ornaments: Christmas tree decorations made from acrylic or wood.

- Acrylic Keychains: Custom-printed keychains.

- Suncatchers & Glass Ornaments: Light-catching and glass-like decorative items.

- Home Decor: Nameplates, standees, and various desk or home gift items.

Outstanding Advantages of UV Printing

Why is UV printing so widely favored by both production facilities and POD sellers? The answer lies in its five major strengths:

- Exceptional sharpness: Because the ink is cured instantly, it does not smudge or bleed. This allows UV printing to reproduce fine strokes, detailed icons, and small text with outstanding clarity.

- Bright and vibrant colors: UV light “locks” the ink on the surface, preserving high saturation, vivid tones, and minimizing the dulling that often occurs with traditional heat-based printing methods.

- The “king” of hard surfaces: This is UV printing’s greatest strength. Most flat, rigid materials acrylic, wood, glass, metal, and PVC can be printed with UV effortlessly and with high fidelity.

- Unique visual effects: For transparent acrylic products, UV printing allows the creation of layered colors, depth effects, and light-passing aesthetics (as seen in suncatchers), enhancing the product’s overall visual appeal.

- Impressive durability: UV prints are resistant to water, sunlight (UV exposure), and scratches. This makes them ideal for long-distance shipping, as the print surface is far less prone to damage.

Limitations Sellers Should Be Aware Of

Despite its strengths, UV printing is not a “magic solution” for every type of product. Sellers need to understand its limitations to avoid choosing the wrong technology.

- Not suitable for fabrics: UV printing cannot be used on T-shirts, hoodies, or any soft, stretchable surfaces. When applied to fabric, the hardened ink layer will crack immediately as the material flexes. (This is where DTG excels.)

- Challenges with complex gradients: When processing real-human portraits or ultra-smooth gradient transitions, UV printing may produce slight dot patterns or visual “noise,” resulting in less natural color blending compared to DTG.

- Perceptible ink thickness: Because UV ink sits on top of the material rather than absorbing into it, customers may feel a slight texture or raised thickness when touching the printed surface. However, for many decor products, this embossed-like effect can actually enhance the premium feel.

Overview of DTG Printing Technology

Understanding DTG does not only help sellers choose the right product lines but also allows them to optimize print quality to satisfy even the most demanding customers.

What Is DTG Printing?

DTG (Direct-to-Garment) is a digital printing method that uses specialized inkjet technology to apply water-based, eco-friendly ink directly onto the surface of the fabric. Unlike decal or DTF (Direct-to-Film) printing, which creates a thick plastic-like layer on top of the garment, DTG ink penetrates deep into the fibers. This integration allows the print to become part of the fabric itself, resulting in a soft, natural feel.

Because of this characteristic, DTG is the most popular choice for producing core POD apparel lines such as:

- T-shirts (Unisex, Ladies)

- Hoodies and Sweatshirts

- Long-sleeve shirts

- Youth shirts

Outstanding Advantages That Make DTG the Dominant Technology in Apparel

Why do most major POD platforms (Printful, Printify, Merchize, and others) prioritize DTG for T-shirts?

- Exceptional color and detail reproduction: DTG is a master at handling complex color transitions. It excels in rendering shadows, textures, and smooth gradients. This makes DTG the only truly reliable choice for portrait designs, anime artwork, or vintage-style graphics.

- Comfortable, soft hand feel: Because the ink absorbs into the fabric rather than sitting on top of it, the printed area does not feel heavy or suffocating. The garment remains breathable, making DTG ideal for warm and humid climates.

- Optimized for personalization: DTG does not require screens or setup time like screen printing. Its fast, flexible workflow allows each shirt to be printed with a different design (such as personalized names) without increasing production cost.

- Perfect compatibility with cotton: The higher the cotton content, the better DTG ink adheres and the more vibrant the colors appear.

Limitations Sellers Must Understand to Avoid Bad Reviews

Although DTG is highly advanced, it still comes with technical constraints that sellers need to consider when preparing design files and selecting base products.

- Strict requirements for design files: To achieve a sharp, high-quality print, the design file must be 300 DPI at the actual print size. If you enlarge a small image without proper upscaling, the print will immediately appear pixelated and blurry on the shirt.

- Dependent on fabric composition: DTG is designed specifically for cotton. When printed on 100% polyester or fabric with a high synthetic content, the ink cannot properly absorb, resulting in faded colors that may wash out easily.

- Challenges with dark garments (White Ink Underbase): When printing on black or dark-colored shirts, the printer must lay down a white underbase before applying the colored inks to ensure accurate color reproduction. This process increases production cost for dark garments and creates a print layer that feels slightly thicker compared to prints on light-colored shirts.

UV vs DTG: The Core Differences Every Seller Must Know

This is the most crucial section to help you define your product strategy. We will compare the two technologies across five essential criteria.

Printing Materials

- UV Printing: Known as the “King of Hard Materials,” UV can print on almost anything: plastic, wood, glass, metal, leather, ceramic, and more. However, UV is incompatible with soft or stretchable materials.

- The reason is simple: once cured, UV ink becomes a hard plastic-like layer. If you print UV on a T-shirt, any stretching or folding of the fabric will cause the print to crack immediately.

- DTG Printing: Considered the “Queen of Fabrics,” DTG is made for cotton fibers. Because the water-based ink absorbs into the fabric, the print can withstand stretching, folding, and movement without cracking or breaking.

- Takeaway for Sellers: Never request UV printing on standard T-shirts, and you cannot use a DTG machine to print on phone cases or other hard surfaces.

Durability

- Physical durability (Scratch/Impact resistance):

- UV printing is the clear winner. Once cured, UV ink forms a hardened layer that offers excellent resistance to scratches, water, and UV sunlight. A UV-printed outdoor sign can withstand rain and sun exposure for years without fading. A UV-printed ornament can last for decades.

- DTG, on the other hand, cannot withstand strong friction because the ink is absorbed into fabric fibers.

- Wash durability (Wash fastness):

- DTG is designed to endure washing. Over time (typically after 30–50 wash cycles), DTG prints will naturally fade evenly, similar to how denim gradually lightens with use.

- UV printing, however, will fail immediately if used on fabric one wash is enough to ruin it. On hard goods like tumblers or ceramic surfaces, modern UV printing can withstand hand-washing, but it is not recommended for high-heat dishwashers, as extreme temperatures may cause the cured ink layer to detach.

Color Vibrancy and Visual Output

- UV Printing: UV produces brighter, glossier, and more eye-catching colors. Because the ink sits on the surface rather than being absorbed, the material does not “mute” the tones. Blacks printed with UV are deep and solid, whites are crisp and bright, and overall saturation is significantly higher. UV printing can also apply a varnish (gloss) layer to create selective highlights for an elevated visual effect.

- DTG Printing: DTG colors tend to be softer, more natural, and more harmonious. On dark garments, the white underbase allows colors to remain vibrant, though DTG will never achieve the glossy finish that UV provides. DTG excels in high-resolution detail reproduction, making it ideal for smoke effects, smooth gradients, or photorealistic images.

Speed and Fulfillment Efficiency

- UV Printing: UV is extremely fast because most materials do not require pretreatment, and the ink cures instantly without additional heat drying. Once printed, the product can be packaged immediately. This is a substantial advantage during Q4 when fulfillment speed is critical.

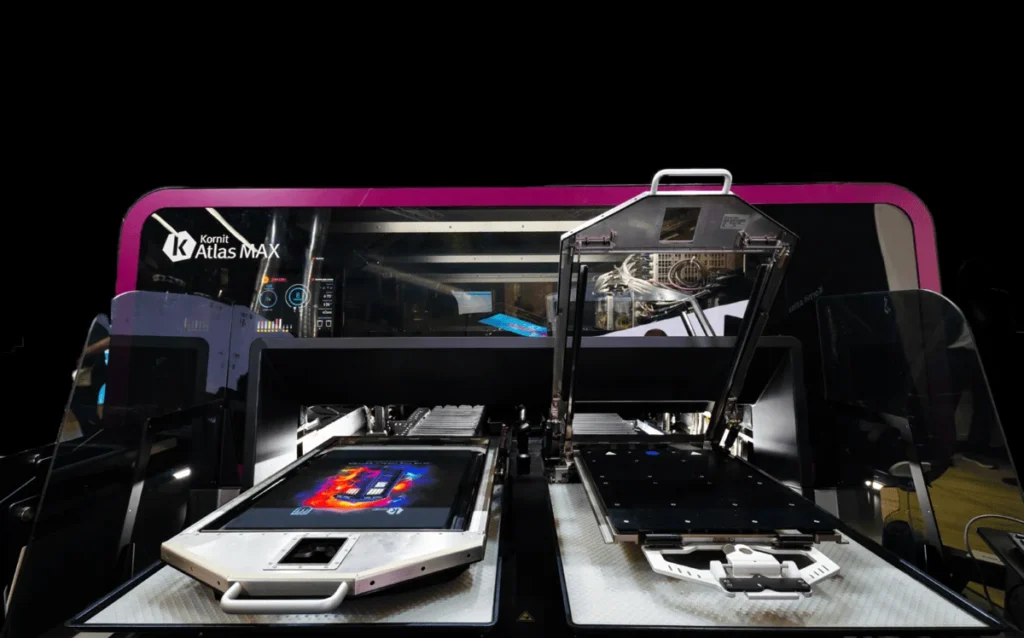

- DTG Printing: DTG is slightly slower due to its multi-step workflow: pretreatment, heat press, printing, and curing. However, modern industrial DTG printers such as Kornit or Brother machines used by major production facilities have significantly improved throughput, making DTG increasingly efficient for high-volume fulfillment.

Cost and Base Price

- UV ink: More expensive than water-based inks. DTG ink: Slightly cheaper, but the overall process is more costly due to labor (pretreating garments) and heat-press equipment depreciation.

- However, when looking at total product base cost in POD:

- UV-printed products (ornaments, keychains) are typically small in size, which results in lower print costs and higher profit margins.

- DTG-printed products (T-shirts, hoodies) have a larger print area, which increases printing costs, but the higher sales volume of apparel compensates for the lower margin per unit.

Which Technology Should POD Sellers Choose? The Perfect Combination Strategy

The answer is not choosing one over the other, but choosing the right tool for the right purpose. A successful POD seller a true “Top Seller” typically diversifies their product catalog and leverages multiple printing technologies strategically.

When Should You Focus on UV-Printed Products?

- Q4 Holiday Season: This is the prime market for UV printing.

- Ceramic Ornaments: The number-one keepsake during Christmas. UV printing ensures family photos, names, and details remain sharp and beautiful for many years.

- Personalized Gifts: Keychains, Spotify plaques, acrylic keepsakes, and commemorative items. Customers buying gifts often prioritize a luxurious, glossy appearance something UV printing delivers exceptionally well.

- Selling on Amazon or Etsy Handmade: UV-printed hard goods typically have lower return rates because they avoid common apparel issues like sizing problems and inconsistencies in print quality. As a result, they generate fewer customer complaints and refunds.

When Should You Focus on DTG-Printed Products?

- Building a fashion brand (Streetwear): If you want to sell designer T-shirts or stylish hoodies, DTG is the only printing method that delivers the quality and feel expected from real fashion labels.

- Year-round selling (Evergreen): T-shirts fulfill a basic, nonstop demand. You can sell apparel all year long from Mother’s Day and Father’s Day to Halloween and the 4th of July.

- Complex designs: If your artwork includes heavy gradients, transparency effects, intricate textures, or detailed fur patterns, DTG will reproduce these elements on fabric with exceptional accuracy.

Printing technology is a core factor that determines product quality and customer satisfaction in the POD industry. Understanding the differences between UV Printing and DTG Printing allows sellers to choose the right product lines, optimize their designs, and avoid common issues such as color mismatch, loss of detail, or outputs that do not match the mockup. UV is best suited for hard-surface products like acrylics, ornaments, and suncatchers, while DTG remains the gold standard for T-shirts, hoodies, and sweatshirts. Selecting the correct printing method not only enhances product quality but also improves conversion rates, reduces refunds, and elevates the overall shopping experience for U.S. customers.

To operate efficiently and maintain consistent quality, sellers should prioritize products fulfilled directly in the United States with a clear, reliable quality control process. FlashShip provides modern UV and DTG printing systems, fast processing speeds, and high stability helping sellers confidently scale their stores and grow revenue year-round. If you are looking for a high-quality fulfillment solution for the U.S. market, explore the product lines and printing technologies offered by FlashShip to achieve the best possible results.